Leveraging Predictive Maintenance to Digitalize the Wind Energy Sector

IoT and predictive maintenance are among IT solutions for the renewable energy sector that have already proven to generate tangible benefits. In this post, we’ll take a closer look at how market leaders are minimizing O&M costs through greater connectivity and better analytics.

Predictive Maintenance for Wind Farms: Common Use Cases

Most wind farm operators leverage SCADA data for remote monitoring and management. While it’s possible to enable predictive maintenance using this source alone, there are two major limitations to its effectiveness:

- Operators can only monitor a limited amount of sensor data, collected from the wind turbines. At the same time, failures often originate from previously unknown and untracked sources, thus making it hard to identify and mitigate the root cause of the failure remotely.

- Most SCADA systems are also programmed in such a way as to alert users only when a certain control threshold is breached. However, when this happens, it might already be too late for preventive measures.

In short, incomplete visibility into the evolving downtime undermines the effectiveness of SCADA-based predictive maintenance.

Arguably, that’s the main reason why operators are actively exploring IoT-driven wind turbine predictive maintenance to complement (or even replace SCADA). Below is a list of use cases illustrating several successful pilots.

Predictive Operation and Maintenance (O&M) for Offshore Wind Farms

O&M costs are among the key barriers hindering the wider production of wind energy. The median operations and maintenance (O&M) cost for a US wind farm is estimated to be between $42,000 and $48,000/MW during the first 10 years of operations. However, as wind turbines age, the O&M costs ramp up too. Between 2016 and 2026, US operators will spend over $400 billion on maintenance activities.

Another report suggests that, on a global scale, O&M costs will rise to $17 billion in 2020. Again, the main reason for this is asset aging, along with a growing volume of installations required to meet the increased green energy demand among the populations. Offshore wind farm operators are facing the most pressure as such installations have 2x-4x higher O&M costs compared to on-shore farms.

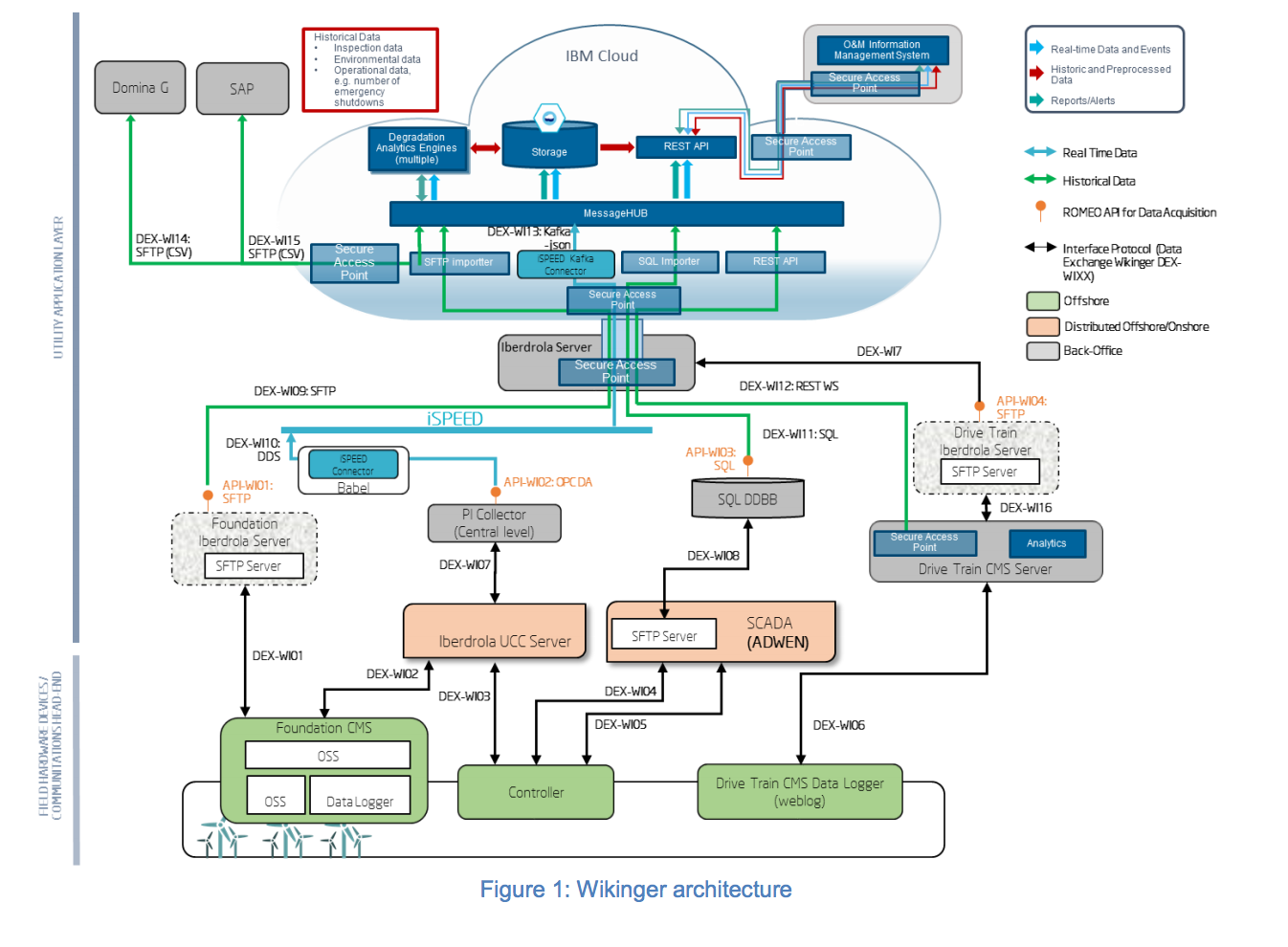

ROMEO project, backed by the European Union’s Horizon 2020 grant, is a research initiative, aimed at reducing the O&M costs of the offshore wind farms. Twelve experienced market players (including IBM Zurich, Siemens, Adwen, and ElectricitéDe France among others, led by Iberdrola Renovables Energia, are working jointly on new IoT predictive wind turbine maintenance system for 3 offshore farms.

In their report, the consortium introduced this proposed architecture for the new platform:

What’s illustrated above is the technical backbone for a three-module O&M system that would support:

- Failure modeling that includes mean time to failure estimation model and mean time to repair estimation model;

- Weather modeling;

- Cost modeling (CAPEX and OPEX).

All the data collected from condition monitoring systems on wind turbines, SCADA and additional sources will be transferred for analytics to the IBM cloud. A predictive maintenance machine learning algorithm will operationalize all the incoming information and translate it into actionable insights. For instance, suggesting the optimal window to dispatch a maintenance team on-site based on sea weather data, duration of navigation and repair, plus asset allocation.

Improved Maintenance Planning and On-Site Visits

Wind turbine farms are prone to unforeseen natural hazards such as lightning strikes, extreme icing, earthquakes, etc. Subsequent unplanned maintenance can stall operations for a long period as technicians are forced to run diagnostics to determine the impact.

IoT sensors can effectively replace humans on the job of doing preliminary damage assessments and make on-site visits more productive. For instance, if lightning strikes one of the turbines, a sensor can capture data about the current that passed through each blade, gauge any changes in performance and pass on the data in real time to the central control system that will alert the team.

The maintenance team, thus, will know exactly which site they need to visit, what impact the strike caused, and which blades need to be diagnosed. During the visit, the team will then only need to stop the affected wind turbines and minimize downtime.

Furthermore, machine learning algorithms can compare the current performance with historic records and scan through the past maintenance report to estimate the current state of the blade and provide technicians with further recommendations on whether it should be checked immediately or if maintenance can be postponed for later. Such data can majorly help optimize maintenance schedules and improve on-site planning visits.

Early Short-Circuit Failures Detection and Prevention

Electrical generators are one of the most critical components in a wind turbine. Any issues with this hardware will decrease operational availability three times more than any other component and have an estimated 30% impact on the cost of wind energy.

Around 30 to 40% of induction motor failures in wind turbines are caused by short-circuits in the stator. The ability to identify these early can significantly reduce maintenance costs. For this purpose, a group of researchers from Brazil proposed using a setup consisting of:

- A microcontroller with the framework;

- Peripheral sensors such as accelerometer MEMs that are connected to the electric generator of the wind turbine.

These would allow to capture real-time data of the vibration and with the help of machine learning models identify the running status of the wind turbine generator and provide operators with a detailed visualization.

The proposed system enables the following benefits:

- Higher data accuracy

- Improved planning of predictive and corrective maintenance

- Minimized on-site visits

- Reduced operating costs.

Wind Turbine Reliability Predictions

IoT hardware modules are versatile and can be programmed to capture an array of different data points that affect the turbine voltage output such as:

- Downwind topologies

- Estimated wind speed and direction

- Effective yaw and pitch angles combinations

With the help of IoT sensors, you can collect the number, the position, the pitch angle, yaw angle and the downwind spacing of the wind turbines. That data is automatically sent to the cloud repository so that the machine learning algorithm can measure the output voltage for each turbine and suggest the optimal setup to maximize energy generation. Moreover, the system can alert operators of sudden weather changes so that they could remotely adjust the settings to prevent failures.

Intelligent De-Icing System Activation

Cold climates have an estimated 10% higher wind power availability. However, harsh operating conditions can easily minimize the obtained gains. Wind turbines in cold climates are more prone to mechanical fatigue, which causes shaft cracks, shattering, tooth breakage and other issues reducing the asset effectiveness.

Moreover, northern farms lose up to 20% of annual energy production due to icing. Already, there’s plenty of ice-protection and de-icing systems available on the market. However, these can balloon operational costs if used un-optimized. IoT technology comes to the fore here, yet again.

Nordex, one of the popular turbine manufacturers, has an effective proprietary de-icing solution that consists of an ice sensor and several heating elements on parts of the leading edge of each rotor blade.

The connected sensor monitors current conditions and sends real-time updates to the operation management system. When early conditions for icing are detected, the heating elements are automatically activated. This reduces the need for the turbine to be shut down for de-icing, thus minimizing downtime.

Coupled with maintenance report data and historic weather trends, the ML algorithm can further estimate when specific turbines are due to inspection so that on-site visits can be planned better.

Remote Diagnostics, Maximizing Uptime and Minimizing O&M Costs

IoT devices can capture a more granular level of insights across different dimensions, ranging from temperature to sound and vibrations. In simple terms, they act as your “eyes” on the equipment, showing the slightest change in operating parameters and detecting anomalies.

Siemens Gamesa published a case study showcasing how they monitor 10,000 remotely connected wind turbines around the world. Every turbine is equipped with 300 sensors, transmitting data to the Siemens Gamesa Remote Diagnostic Center for further analysis. In addition, the company uses digital twinning technology to enhance asset management and improve spare parts forecasting with early failure prediction.

The company’s digital twins are based on a combination of real-time performance data and a collection of historical vibration data since 2004. The system uses neural networks to compare the inputs and locate early damage indication patterns. Specifically, their algorithms can remotely detect 99% of drive-train damage, such as main bearing damage or gear-tooth cracks.

Transition from Calendar-Based to Condition-Based Maintenance

By understanding how wind turbines operate in real time, you can switch from costly planned scheduled maintenance to a more effective condition-based one.

Predictive models can operationalize data obtained from sensors, as well as from other sources such as service reports or historical performance trend reports to determine when and how each wind turbine should be serviced. Specifically, advanced predictive models can estimate the need for servicing months and even years in advance. This allows wind farm owners to carry out maintenance on an as-needed basis, reducing logistics and material costs, as well as potential downtime.

Enhanced Visibility and Control

Using data obtained from connected sensors, you would be able to create detailed digital representations of your turbines. Operators will be able to switch between the general farm overview and individual wind turbines to gauge performance and identify potential wind turbine maintenance issues early on.

State-of-the-art predictive maintenance systems now allow engineers to:

- Receive single point operational reporting on different parameters ranging from temperature to oil inspection.

- Review the state of each asset in detail and assess its performance in real time.

- Monitor asset health and identify any changes in performance early on.

Having greater visibility and predictive components within your system also lets you estimate how certain issues will impact the turbines within the next several weeks/months. For instance, you can estimate that a certain deviation in the vibration pattern will not negatively affect the turbine within the next 3 months. This means you have room to plan an on-site visit within the optimal time and remotely set the optimal performance parameters for the turbine before the engineer arrives.

State-of-the-art predictive maintenance systems now allow engineers to:

- Receive single point operational reporting on different parameters ranging from temperature to oil inspection.

- Review the state of each asset in detail and assess its performance in real time.

- Monitor asset health and identify any changes in performance early on.

Having greater visibility and predictive components within your system also lets you estimate how certain issues will impact the turbines within the next several weeks/months. For instance, you can estimate that a certain deviation in the vibration pattern will not negatively affect the turbine within the next 3 months. This means you have room to plan an on-site visit within the optimal time and remotely set the optimal performance parameters for the turbine before the engineer arrives.

Cost-Efficiency

All of the use cases described above pursue one ultimate goal – trim the O&M costs through improved asset performance.

The ROI of implementing IoT-driven predictive maintenance will vary significantly from project to project. However, one case study provides some ballpark figures. An energy supplier expects to obtain $10 million in ROI from one wind farm over the next 5 years. Savings from reduced downtime alone are estimated to be $1.25 million per farm. In addition, a 5% revenue improvement per wind farm will result from optimized turbine performance through preventive maintenance.

Furthermore, the estimated cost savings from lower inventory, labor costs and higher maintenance efficiency will round up to 20% per wind farm.

To Conclude

More and more energy suppliers are realizing the benefits of wind energy production. However, achieving lean, effective and most importantly – unified turbine operations remains a challenge. A single wind farm may include thousands of turbines, installed at difficult-to-reach locations and harsh climate zones. Thus, to remain profitable and competitive, operators must seek new ways for optimizing loads, asset usage and lifetime spans, plus maintenance schedules.

Connected sensors, coupled with predictive analytics algorithms, have emerged as strong contenders to maximize reliability and performance. At the end of the day, wind farm owners who have access to the most accurate, qualitative data will be leading the predictive maintenance wave and realizing the benefits outlined above.

If you are ready to explore industrial IoT and predictive analytics, get in touch with us today. Infopulse team has significant experience in the energy sector and is ready to help you improve your operations and profitability with new tech solutions.

![CX with Virtual Assistants in Telecom [thumbnail]](/uploads/media/280x222-how-to-improve-cx-in-telecom-with-virtual-assistants.webp)

![Power Apps Licensing Guide [thumbnail]](/uploads/media/thumbnail-280x222-power-apps-licensing-guide.webp)

![Expanding NOC into Service Monitoring [thumbnail]](/uploads/media/280x222-best-practices-of-expanding-telecom-noc.webp)

![Cloud-Native for Banking [thumbnail]](/uploads/media/cloud-native-solutions-for-banking_280x222.webp)

![Generative AI and Power BI [thumbnail]](/uploads/media/thumbnail-280x222-generative-AI-and-Power-BI-a-powerful.webp)

![Data Governance in Healthcare [thumbnail]](/uploads/media/blog-post-data-governance-in-healthcare_280x222.webp)

![Super Apps Review [thumbnail]](/uploads/media/thumbnail-280x222-introducing-Super-App-a-Better-Approach-to-All-in-One-Experience.webp)

![SAP Service Insight [thumbnail]](/uploads/media/Service Insight-Infopulse-SAP-Vendor-280x222.webp)